Ultrasonic cutting/sealing technology

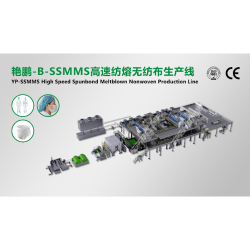

Category: Nonwoven production machinery (Other nonwoven production equipment & accessories)

Exhibitor: SPOOLEX

Booth No: J136

Characteristic

With the introduction of 𝗶𝘁𝘀 𝗳𝗶𝗿𝘀𝘁 𝗿𝗮𝗻𝗴𝗲 𝗼𝗳 𝘂𝗹𝘁𝗿𝗮𝘀𝗼𝗻𝗶𝗰 𝘀𝗼𝗹𝘂𝘁𝗶𝗼𝗻𝘀 𝗶𝗻 𝟭𝟵𝟳𝟱, Decoup+ the Ultrasonics Division of Spoolex, is now recognized as a 𝘄𝗼𝗿𝗹𝗱𝘄𝗶𝗱𝗲 𝗲𝘅𝗽𝗲𝗿𝘁.

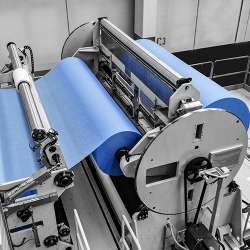

We offer a complete range of 𝗲𝗳𝗳𝗶𝗰𝗶𝗲𝗻𝘁 𝗮𝗻𝗱 𝘂𝘀𝗲𝗿 𝗳𝗿𝗶𝗲𝗻𝗱𝗹𝘆 𝗺𝗮𝗻𝘂𝗮𝗹 𝗱𝗲𝘃𝗶𝗰𝗲𝘀 𝗼𝗿 𝘄𝗼𝗿𝗸𝘀𝘁𝗮𝘁𝗶𝗼𝗻𝘀 to perform, depending on your needs, cutting and/or sealing operations on any thermofusible fabrics

𝗠𝗮𝗶𝗻 𝗮𝗱𝘃𝗮𝗻𝘁𝗮𝗴𝗲𝘀:

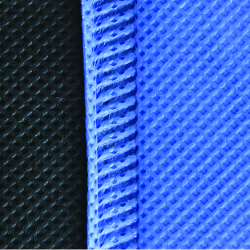

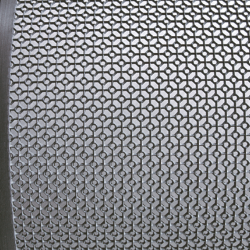

• 𝗤𝘂𝗮𝗹𝗶𝘁𝘆: No change of original characteristics of the fabric, nor burning neither yellowing, nor overthickness

• 𝗥𝗲𝘀𝗶𝘀𝘁𝗮𝗻𝗰𝗲: strong and strengthened edges, without any fraying and allowing an immediate use of the fabric for more efficiency on final make-up operations!

• 𝗥𝗮𝗽𝗶𝗱𝗶𝘁𝘆: a cutting - sealing operation realized in one single pass without any additional material

• 𝗦𝗮𝗳𝗲𝘁𝘆: no risks of burns or irritating smoke for operator

𝗠𝗔𝗡𝗨𝗔𝗟 𝗗𝗘𝗩𝗜𝗖𝗘𝗦:

T̲ ̲3̲0̲0̲W̲ for straight cutting

• Compact and ergonomic device to obtain, in one single pass, clean and strong edges

• Available in 2 configu¬rations: Standard for all kind of fabrics or specific for screen and plastified fabrics

• Can be used on a table or into a U track

P̲ ̲3̲0̲0̲W̲ for straight or shape cutting

• Compact and ergonomic device to obtain, in one single pass, clean and strong edges

• Flexible: depending on sonotrode, use this device to perform cutting, spot welding or continuous welding operations!

𝗪𝗢𝗥𝗞𝗦𝗧𝗔𝗧𝗜𝗢𝗡𝗦:

M̲i̲n̲i̲ ̲P̲r̲e̲s̲s̲ for various operations

• Versatile: press cutting or press welding depending on counter-tools

• Easy to use: repeatability and precision

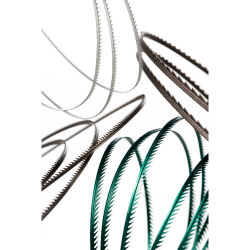

W̲e̲l̲d̲i̲n̲g̲ ̲s̲t̲a̲t̲i̲o̲n̲ for stitching operation:

• Ergonomic and simple to use

• Adapted for small and medium size series

• Resistant weldings

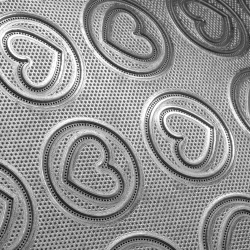

• Different wheels patterns available

Other Products

Products you may be interested in

Highest Rated Products